Tradeprint’s New Offerings

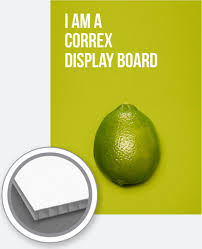

Bespoke-size display board is a new and unique offering by Tradeprint. It will help customers a great deal to reach out to new markets.

“When we brought in the fixed sizes it was a bit of an experiment,” said Barrett-Bunnage, “but what we’ve done now is brought in bespoke sizing and pricing with our simplest and quickest interface yet and we are able top offer some of the lowest prices in the UK for large format products.” From Now onwards, the products will be priced in square metre instead of pricing per product, he further explained.

Tradeprint Bespoke-size display board

“We see huge potential in the large-format market. We want to be a one-stop shop for our customers and so we need to carry a full range of products. We are introducing this to small commercial printers and showing them that there are other markets to tap. We want to grow with those businesses,” he explained.

“Because we are part of a group like Cimpress we can leverage that to maximise our volume discounts from the supplier and then pass it on the customer,” he said. “Our price point looks to be competitive but not hugely disruptive – we want to fit in with the rest of the market,” he added.

He explained: “We are a trusted name, our standards and quality are well-known and we’ve been growing exponentially. The major market difference between us and others out there is the price point, but we don’t want to be cheapest because a large element of what we supply is the whole package. We make a lot of effort not to be value-oriented.”

“Price wars are a huge issue and it’s inevitable people will start them, which means the rest of the market has to respond, but it’s not something that helps the industry. It’s not sustainable.”

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

10 Jolting facts about coffee

It is a paradisematic country, in which roasted parts of sentences fly into your mouth. Even the all-powerful Pointing has.

Lithgo Press enhances its capacity with Horizon

Lipthgo has procured Horizon StitchLiner 5500. It will help to create a more flexible bindery and help improve the efficiency of its operations. Horizon StitchLiner 5500 is a fully automated solution and it comes in 03 VAC-1000 tower collators. Also the product comes with icon based colour touch screen establishing quick setup, an ACF-30 Accumulator having scoring along with, plow-folding feature and a heavy-duty HTS-30S 3-Knife Trimmer.

Horizon StitchLiner 5500

The managing director of Lithgo, Mike Atkinson, said: “We also have a Heidelberg ST300 but with both systems we can now choose quite late in the day which one to use. As the StitchLiner is quick and easy to set up it is perfect for short runs but its quality and robustness means it can also handle longer runs too.

“We liked the StitchLiner because it takes sheets that were planned in a such a way that they could be traditionally folded. That means we can plan work with traditionally folded sections. We looked at other solutions but they didn’t do that.”

Graphic Arts (UK) New Ownership

Alan Buck, 72, the owner of Graphics Arts (UK) and its subsidiaries Concept4 Creative and Printoff Graphic Arts has retired and the company is sold out to an MBO team.

On the occasion of 40th anniversary of the company, the decision was made out. MBO team consists of 03 members. These are Alex Buck, who is the son of Alan and the technology director of the company. The other 02 members are Jason Tomlinson, the finance director and Jane Cleaver the managing director of the company. All of these members will remain in their existing roles within the company.

MBO Team

Cleaver explained that they were in discussion since the start of this year and finally ended up with a quick deal.

She said: “There wasn’t a lot of nitty gritty, Alan wanted this to happen, we wanted it to happen and we were able to work through it very swiftly.

“As we celebrate the 40th anniversary of the business this has been very timely. Alan is very confident that we will be able to take things further forward for him and we are all excited at the opportunity.”

All of these MBO members are in business for more than 20 years.

“We aren’t looking for much change, we have from Printoff’s point of view invested in a new web-to-print solution that has taken traction,” added Cleaver.

“We feel we can press forward with that and embrace the technology that is out there and feel we are quite unique because of what we offer as a group of companies. So we will be embracing new technologies but continuing to invest in traditional print.”

This is a good notion that a company is sold out to internal members. MBO members are already involved in the operations and progress of the company, so there wouldn’t be much change in the management.

Park Communications Invested A Great Deal In Finishing

The London based company Park Communication has almost invested £200,000 for in house lay-flat binding and die-cutting.

The company contains 130 staff members and is growing rapidly. It has purchased a Kisun Digi Binder DB-440 and a Heidelberg SBD Zenith and they are installed in the company premises.

Kisun digi binder db440

Heidelberg SBD Zenith

Alison Branch, the managing director of Park Communication explained that besides outsourcing these operations, they have brought in their own machine to increase the efficiency and reduce the cost. The firm said that they have rigorously tested these machines before bringing these in house.

Branch said: “A lot of our customers are in the property and fashion markets, and particularly in property they love to use double-page spreads because this really maximises the impact of the imagery.

“So property developers, builders and design agencies love lay-flat binding and we were finding there was an increased customer requirement and it’s much easier for us to keep the process in-house; it’s faster, more cost-effective, we reduce carbon emission and it’s just much easier to control the process.”

The lay-flat binder provides strength to binding as the binder sandwiches the two sheets and performs its tasks perfectly.

“The Zenith was brought in as we were finding volumes building up, so we said, ‘Right, this is the chance to internalise’,” added Branch.

“The BBC rang me and said there was good news on unemployment figures and they wanted to present those against the backdrop of a busy, efficient manufacturing facility,” said Branch.

“Their research team had identified companies that might be appropriate and through that they had identified Park.”

It is a good notion to have further investment in bringing up-to-dated machines in-house. It saves time and considerable cost for the company.